Methodist Church

Bedford, PA

Opus 133

Current Specifications

| Great 8' Open Diapason 61 pipes 8' Melodia 73 pipes 8' Dulciana 49 pipes 8' Unda Maris 49 pipes 4' Principal 61 pipes 4' Hohl Flute (Extension) 2' Fifteenth 61 pipes 1-1 /3' Mixture 183 pipes 8' Trumpet (Swell) Chimes Great 16-4 Great Unison Off Swell to Great 16-8-4 |

Swell (enclosed) 16' Bourdon (Extension) 8' Gedeck 85 Pipes 8' Salicional 49 pipes 8' Voix Celeste 49 pipes 4' Geigen Principal 61 pipes 4' Flute Harmonic 61 Pipes 2 2/3' Nazard (Extension) 2' Flauino (Extension) 16' Contra Trumpet (TC) (Extension) 8' Trumpet 73 Pipes 8' Oboe 61 Pipes 4' Clarion (Extension) Tremolo Swell 16-4 Swell to Unison Off 18 ranks of pipes

Design: Mark W. Steiner |

Pedal 32' Resultant (Bourdon) 16' Bourdon 56 Pipes 16' Leiblich Gedeckt (Bourdon) 8' Principal 44 Pipes 8' Bourdon (Extension) 4' Choral Bass (Extension) 4' Bourdon (Extension) 8' Trumpet (Swell) 4' Clarion (Swell) Great to Pedal 8-4 Swell to Pedal 8-4 |

|

Introduction

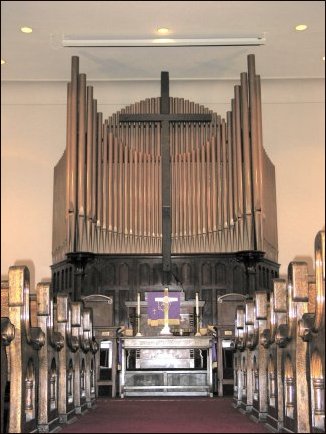

"When one enters the

sanctuary of the Bedford United Methodist Church,

the eyes are immediately drawn to the majestic musical instrument at

the far end behind the pulpit. That instrument is a large pipe organ

built by the Estey Organ Company which has occupied the same space in

the church for nearly 100 years.

The Estey Organ Company

"The Estey Organ Company

of Brattleboro, Vermont, was established by

Jacob Estey in 1855, the culmination of reed instrument manufacturing

that began in Brattleboro in 1846. Throughout the 19th century, the

firm made many styles of melodeons and reed organs, which rapidly made

the name of Estey world-famous. The building of pipe organs was added

in 1901 and 3,261 of them were shipped from the Birge Street factory

until the firm closed in 1961.

Estey Opus #133

"The Bedford United Methodist pipe organ is Opus #133,

manufactured in

Brattleboro, Vermont, in 1904 by the Estey Organ Company. It is

identified by the number 133 etched on its pipes. This number was used

to gain access to a business folder held by the Estey Organ Museum

pertaining to organ 133. From documents located in the business folder,

the early history of the organ unfolded."On February 6, 1904, the Estey Organ Company and the Bedford Methodist Episcopal Church entered into an agreement requiring Estey to build and install a pipe organ for the church. The contracted price was $2,100. There is some evidence to indicate that the Andrew Carnegie Foundation reimbursed the church for the organ’s cost in 1905. Minutes of the Thirty-seventh Session of the [Methodist] Central Pennsylvania Annual Conference includes the following statement: “Through

the generosity of Mr. Andrew Carnegie and the loyal liberality

of our gracious

people at that place an organ costing $2,400 was placed in the church at Bedford.” "Its value for insurance purposes in 1956 was $13,200 and in 2004 that value has increased to $320,000. "The organ was shipped and installed in August 1904 making it nearly 100 years old today. It was installed that same month and, with relatively minor problems, has been rendering its melodious notes for over 99 years. The Breath of Life

"An organ’s wind supply has been described as its “breath

of life.” Its

pipes require a supply of pressurized air in order to sound at all.

Moreover, the supply of wind must be reliable, and it must be regulated

in volume and pressure so that the pipes can speak properly. This

pressurized air was the result of a piston connected to feeders which

in turn were attached to bellows. Feeders consisted of two pieces of

wood held on by leather that moved up and down opposite each other and

forced air into the bellows, thereby supplying air to the organ.

Feeders in the very early pipe organs were pumped by hand; however hand

pumping was ultimately replaced by using a water motor and the hand

pump remained on site as a back-up. It was common to have both the

water motor and the hand pump, as many thought that water pressure was

still too unreliable to use as a regular source of power for the

bellows. The pumping action that initially powered Opus #133 came from

a water motor. By the early 1920’s electric motors were becoming

popular, the feeders eliminated and an air line put directly into the

bellows to supply air to the organ. The water motor which ran Opus #133

was replaced by an electric motor ($215) in 1920 and the leather

covered chest pneumatics were replaced in 1923. In those days,

maintenance cost the church $25 for two semi-annual visits. On one

occasion, after the church had complained of a particular unexplained

problem, Estey quickly found the unusual answer as shown in this

correspondence, as follows:“We just received your

letter of the 1Oth. Enclosing a pneumatic taken

from organ #133,

Bedford, PA. Which plainly shows to have been eaten by rats. We hope you pointed out to these people the necessity of taking some measures to prevent further damage in this way.” "Opus #133 was given a complete rebuild in 1966 - the console by Schantz and the organ by Kennedy - Pittsburgh, Pennsylvania. There are two plaques on the console to that effect. The Church Council agreed in 2003 that a major renovation would be needed to preserve the organ for the years ahead. That renovation was completed in July, 2004 by the Steiner-Murphy Organ Company of Cumberland, Maryland. This was a complete renovation along with the addition of a cymbelstern and five ranks which included trumpets and mixtures. "It is interesting to note that of the large visible pipes seen closest to the congregational area only seventeen are working pipes. The remainder are decorative in nature and have no musical function. There is some anecdotal evidence that the organ’s pipes have been painted white, lavender and the current gold tone through the years. As Steiner Murphy was disassembling the organ for transport to Cumberland, a faux art rendering was discovered on the back wall, previously hidden by the organ. It has since been painted over. "The first organist to perform using Opus #133 was a Bedford native, Miss L. Durbin Shuck (1866 - 1948). She was a daughter of Samuel and Annie (Durbin) Shuck, was an honor student at the local high school, graduated at Chautauqua after a four-year music course, attended Peabody Conservatory in Baltimore and studied pipe organ with a teacher at Woman’s College. She was a member of the Bedford Methodist Church and its organist for 58 years, from 1889 until February 1948. For 40 years she was Bedford’s best-known music teacher and had many students who took an honored place in the musical world. "The music of Opus #133 has spiritually uplifted and thrilled literally thousands of persons, church members, visitors and other audiences as well. With this current renovation, audiences will be able to enjoy the same extraordinary music throughout another century." - Organ Rededication

Program, August 29, 2004

|