Flue Pipe Construction |

Metal Flue Introduction |

Metal Flue Bodies |

Metal Flue Mouths

Wooden Flue Introduction |

Wooden Flue Bodies |

Wooden Flue Mouths

Flue Pipe Construction |

Metal Flue Introduction |

Metal Flue Bodies |

Metal Flue Mouths

Wooden Flue Introduction |

Wooden Flue Bodies |

Wooden Flue Mouths

Flue pipes (usually

called simply "flues") have no moving parts. Their sound is produced when

a stream

of air is focused onto a sharp edge - - the upper lip of a flue pipe. As the wind

strikes the lip, its

smooth flow is disturbed. In the resulting disturbance, a vibration is set up in the

air column

contained in the pipe body, producing an audible sound wave. A similar structure and

result can

be seen in the mouth of a recorder, which produces its sounds in the same way.

Flue pipes (usually

called simply "flues") have no moving parts. Their sound is produced when

a stream

of air is focused onto a sharp edge - - the upper lip of a flue pipe. As the wind

strikes the lip, its

smooth flow is disturbed. In the resulting disturbance, a vibration is set up in the

air column

contained in the pipe body, producing an audible sound wave. A similar structure and

result can

be seen in the mouth of a recorder, which produces its sounds in the same way.

Flue pipes have two primary parts, the foot and the body. Although

these names are used for both metal and wooden flues, there are other differences in

their

construction, according to the material being used. These differences are examined in

detail

below.

The body of metal flues is typically circular in horizontal cross section, and it may be either cylindrical or conical in shape. The top of the body may be either open, closed or partially closed.

When the pipe is open, the

end may be

treated in one of several ways. The first method is to cut the pipe to the correct

length to obtain

the desired pitch. Because changes in temperature and the density of the surrounding

air can have

an effect on pitch, these pipes may be altered slightly by having the edges turned

slightly out, or

slightly in to modify the pitch. This approach to pitch modification is called

coning or cone tuning, and must be done very carefully. The photograph

shows

two pipes from a 2' Principal that have been coned in opposite ways.11

When the pipe is open, the

end may be

treated in one of several ways. The first method is to cut the pipe to the correct

length to obtain

the desired pitch. Because changes in temperature and the density of the surrounding

air can have

an effect on pitch, these pipes may be altered slightly by having the edges turned

slightly out, or

slightly in to modify the pitch. This approach to pitch modification is called

coning or cone tuning, and must be done very carefully. The photograph

shows

two pipes from a 2' Principal that have been coned in opposite ways.11

The second treatment for the

top of a flue

pipe is to fit the open end with a movable sleeve or collar of metal. The

collar is not

fastened to the body of the pipe, but is held tightly in place by tension, leaving it

free to be moved

up or down to affect pitch changes. Even when the pipe is made of spotted metal, a

thinner, less

malleable sheet of metal is used for the collar, as seen in this photograph.

12

The second treatment for the

top of a flue

pipe is to fit the open end with a movable sleeve or collar of metal. The

collar is not

fastened to the body of the pipe, but is held tightly in place by tension, leaving it

free to be moved

up or down to affect pitch changes. Even when the pipe is made of spotted metal, a

thinner, less

malleable sheet of metal is used for the collar, as seen in this photograph.

12

Finally, open pipes may have

two small cuts

made into the material of the body at the open end. The metal between the cuts may

be rolled

down to shorten the effective length of the body, as seen in the photograph to the

right. 13

The resulting curl of metal is usually called the "scroll," and the process of tuning

a pipe in this

manner is referred to as "scroll tuning" or "scrolling."

Alternately a separate, movable piece of metal can be fastened to the body of the

pipe. This can

then be moved up or down to make a similar change.

Finally, open pipes may have

two small cuts

made into the material of the body at the open end. The metal between the cuts may

be rolled

down to shorten the effective length of the body, as seen in the photograph to the

right. 13

The resulting curl of metal is usually called the "scroll," and the process of tuning

a pipe in this

manner is referred to as "scroll tuning" or "scrolling."

Alternately a separate, movable piece of metal can be fastened to the body of the

pipe. This can

then be moved up or down to make a similar change.

When a metal pipe is closed at

the top, it is

usually fitted with a cap, which is slightly larger in diameter than the pipe

and fits over the

end. The inner rim of the cap is usually lined with felt, so that air pressure will

not cause a rattle,

and the felt is often folded over the outer rim of the cap and is visible. Closed

metal pipes can

often be recognized by the presence of a felt band marking the end of the cap, as

seen in this

photograph.

14

When a metal pipe is closed at

the top, it is

usually fitted with a cap, which is slightly larger in diameter than the pipe

and fits over the

end. The inner rim of the cap is usually lined with felt, so that air pressure will

not cause a rattle,

and the felt is often folded over the outer rim of the cap and is visible. Closed

metal pipes can

often be recognized by the presence of a felt band marking the end of the cap, as

seen in this

photograph.

14

Two types of partially closed

metal pipes are common. In the form seen at the right, an opening in the cap is

extended by a

smaller metal cylinder.

16 In some cases the cylinder is

extended downwards into the body of the

pipe. Pipes made like this are called in different languages Chimney flute,

Rohrflöte,

or Flûte à cheminée in description of their appearance.

Two types of partially closed

metal pipes are common. In the form seen at the right, an opening in the cap is

extended by a

smaller metal cylinder.

16 In some cases the cylinder is

extended downwards into the body of the

pipe. Pipes made like this are called in different languages Chimney flute,

Rohrflöte,

or Flûte à cheminée in description of their appearance.

Alternately, the cap itself may

be

made in a

conical shape with an opening at the smaller end of the cone. The photograph to the

left shows the conical

cap of a Koppelflöte with the opening visible in its top.

17 A Spillflöte has

a

cap with a similar, more elongated shape.

Alternately, the cap itself may

be

made in a

conical shape with an opening at the smaller end of the cone. The photograph to the

left shows the conical

cap of a Koppelflöte with the opening visible in its top.

17 A Spillflöte has

a

cap with a similar, more elongated shape.

Although most flues - - whether

the bodies are made of wood or metal, or whether they are

cylindrical or conical - - are straight, their bodies may in fact be mitered,

or bent at one or

more angles. These changes in the shape of the body are made only when space or

other

limitations must be considered. Mitering a pipe has only a small effect on the

quality of the sound,

but the change of direction in an open pipe can cause the projection of the sound to

be different.

In metal pipes, like the one in the photograph to the right, mitering can lead to

instability in the

body. If a soft metal is used (one with high lead content, for example), extra

support must be

provided or the pipe can be pulled apart by its own weight. The pipe in the

photograph is made of

zinc and is stable.

15

Although most flues - - whether

the bodies are made of wood or metal, or whether they are

cylindrical or conical - - are straight, their bodies may in fact be mitered,

or bent at one or

more angles. These changes in the shape of the body are made only when space or

other

limitations must be considered. Mitering a pipe has only a small effect on the

quality of the sound,

but the change of direction in an open pipe can cause the projection of the sound to

be different.

In metal pipes, like the one in the photograph to the right, mitering can lead to

instability in the

body. If a soft metal is used (one with high lead content, for example), extra

support must be

provided or the pipe can be pulled apart by its own weight. The pipe in the

photograph is made of

zinc and is stable.

15

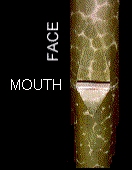

In metal pipes the foot is

usually conical and expands from a small base to the point at which it joins the

body. An inset

plane around the joint between foot and body is called the face, and an

opening into the

pipe - - the mouth - - is cut into the pipe on that plane above the

languid, an

internal horizontal plate that almost completely closes off the foot from the body.

In metal pipes the foot is

usually conical and expands from a small base to the point at which it joins the

body. An inset

plane around the joint between foot and body is called the face, and an

opening into the

pipe - - the mouth - - is cut into the pipe on that plane above the

languid, an

internal horizontal plate that almost completely closes off the foot from the body.

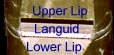

Wind enters the pipe through

the toe, appropriately located at the base of the foot, and exits the foot

through the

flue, a narrow opening between the languid and the lower lip. These

two parts

focus the wind onto a relatively sharp edge called the upper lip.

Wind enters the pipe through

the toe, appropriately located at the base of the foot, and exits the foot

through the

flue, a narrow opening between the languid and the lower lip. These

two parts

focus the wind onto a relatively sharp edge called the upper lip.

A pipe mouth may have two additions made externally.

Ears

are vertical metal plates attached at the left and right of the mouth. They aid in

focusing the wind onto the upper lip. The pipe in the photograph to the right is a

small

Koppelflöte; the cap extends downward to the top of the ears.

23

Ears

are vertical metal plates attached at the left and right of the mouth. They aid in

focusing the wind onto the upper lip. The pipe in the photograph to the right is a

small

Koppelflöte; the cap extends downward to the top of the ears.

23

A harmonic bridge,

commonly called a beard, is a horizontal plate attached below the lower

lip, or a

wooden

dowel placed between the ears. The photograph to the left shows a pipe mouth with

ears and a

wooden bridge.

24

A harmonic bridge,

commonly called a beard, is a horizontal plate attached below the lower

lip, or a

wooden

dowel placed between the ears. The photograph to the left shows a pipe mouth with

ears and a

wooden bridge.

24

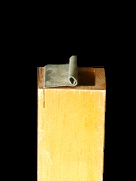

The choice of

materials has an effect on the shape a pipe assumes, and wooden pipes are most often

square or

rectangular in horizontal cross section. As the photograph to the left shows, even

wooden pipes

usually have a cylindrical extension at their base, and that extension will often

terminate in a lead

tip which allows the toe hole to be opened or closed without damage to the wood.

25

The choice of

materials has an effect on the shape a pipe assumes, and wooden pipes are most often

square or

rectangular in horizontal cross section. As the photograph to the left shows, even

wooden pipes

usually have a cylindrical extension at their base, and that extension will often

terminate in a lead

tip which allows the toe hole to be opened or closed without damage to the wood.

25

Two exceptions to wooden pipes having a rectangular shape are noteworthy:

The body of a wooden flue may be either open, closed or partially closed, but the construction of the upper end of wooden pipe bodies is different from that found in metal pipes.

Open wooden bodies

cannot be

cone tuned, as can metal ones, because wood cannot be flared or coned inward to

effect a pitch

change without destroying the material. Sliding tuning collars are also not found on

wooden

pipes. They are instead fitted with a slot and a movable wooden slide that can be

used to change

the effective resonating length of the body.

26

Open wooden bodies

cannot be

cone tuned, as can metal ones, because wood cannot be flared or coned inward to

effect a pitch

change without destroying the material. Sliding tuning collars are also not found on

wooden

pipes. They are instead fitted with a slot and a movable wooden slide that can be

used to change

the effective resonating length of the body.

26

Closed wooden bodies are

usually fitted with a stopper made of wood and padded with leather. The

stopper is made

to fit inside the body and usually has a handle, or even a cord, attached to its top

so that its depth

can be adjusted. The photograph shows a typical stopped pipe with a stopper from

another pipe

beside it.

27

Closed wooden bodies are

usually fitted with a stopper made of wood and padded with leather. The

stopper is made

to fit inside the body and usually has a handle, or even a cord, attached to its top

so that its depth

can be adjusted. The photograph shows a typical stopped pipe with a stopper from

another pipe

beside it.

27

Partially closed wooden

pipes

are made in several different ways. The most common way is found when a piece of

metal is

attached to one side of the top of a wooden body. The flap of metal is then rolled

back, or

scrolled, to partially uncover the top of the pipe.

28

Partially closed wooden

pipes

are made in several different ways. The most common way is found when a piece of

metal is

attached to one side of the top of a wooden body. The flap of metal is then rolled

back, or

scrolled, to partially uncover the top of the pipe.

28

A less

common means of

partially

closing a wooden pipe is found in the case of wooden Chimney flutes. In these pipes,

which are

much less common than metal Chimney flutes, a hole is bored through the wooden handle

of the

stopper. The wooden Rohrflöte shown in the photograph to the left has been made

by

fitting a new wooden Gedeckt with stoppers from an older pipe.

29

A less

common means of

partially

closing a wooden pipe is found in the case of wooden Chimney flutes. In these pipes,

which are

much less common than metal Chimney flutes, a hole is bored through the wooden handle

of the

stopper. The wooden Rohrflöte shown in the photograph to the left has been made

by

fitting a new wooden Gedeckt with stoppers from an older pipe.

29

The body of a wooden pipe by

be mitered, or turned at an angle. Particularly in the case of stopped pipes, there

is no change in

the projection of sound, because the mouth, through which the sound is heard in a

stopped pipe,

can have the same placement as unmitered pipes in the same rank. If a miter is

extensive, a

wooden pipe can become unstable without support, as can a metal pipe. The photograph

to the

right shows one way of building a wooden mitered pipe so that there is little

possibility for

instability. The side of the pipe uses one piece of wood for both sections of the

miter. A blue line

shows the internal wall that separates the two sections, so that the body consists of

one resonating

space that has been folded over and covered with one piece of wood.

30

The body of a wooden pipe by

be mitered, or turned at an angle. Particularly in the case of stopped pipes, there

is no change in

the projection of sound, because the mouth, through which the sound is heard in a

stopped pipe,

can have the same placement as unmitered pipes in the same rank. If a miter is

extensive, a

wooden pipe can become unstable without support, as can a metal pipe. The photograph

to the

right shows one way of building a wooden mitered pipe so that there is little

possibility for

instability. The side of the pipe uses one piece of wood for both sections of the

miter. A blue line

shows the internal wall that separates the two sections, so that the body consists of

one resonating

space that has been folded over and covered with one piece of wood.

30

The mouths of wooden pipes are generally built as a part of the body. The languid is replaced by the block, a piece of wood that is as wide as the interior dimension of the pipe body. This block of wood has a cylindrical hole drilled in its lower surface, through which the cylindrical foot is attached. Another hole is bored from the front of the block, intersecting the space made be the first hole. A small plate of wood, called the face, is attached to the front of the block. The face has a small amount of material removed from the side that will be in contact with the block. The small space fits over the hole so that wind can enter it. The wind then moves through the space between block and face and exits through the flue formed by the top of the face and the block.

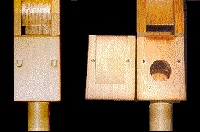

The photograph at the left

shows two views of the mouth of a wooden

pipe. In the first view, the mouth appears as it normally does in a working pipe.

In the second,

the face has been removed and turned over to show its back side. The shallow cut,

which covers

most of the area of the plate, is visible on the face.

31

The photograph at the left

shows two views of the mouth of a wooden

pipe. In the first view, the mouth appears as it normally does in a working pipe.

In the second,

the face has been removed and turned over to show its back side. The shallow cut,

which covers

most of the area of the plate, is visible on the face.

31

© 1998, James H. Cook